Infrared Thermography

Infrared Moisture Surveys are technologically advanced roofing inspections performed using specialized drones and handheld devices.

Benefits

Targeted Roof Repairs

Find roof repairs easy and fast

Damage Prevention

Moisture left unchecked in a roofing system can compromise the structural integrity of a building

Periodic Monitoring

Monitor the health of your roof for preventative maintenance

Why Infrared Roof Scans?

These inspections provide property owners with a clear and discernible picture of the moisture present in their roofing system. Equipped with this evidence, Parsons Roofing Company can recommend accurate, fact-based solutions that meet the unique needs of each property.

Infared Thermography Benefits

What are Drone Scans?

- Infrared Moisture Surveys are technologically advanced roofing inspections performed using specialized drones and handheld devices. These inspections provide property owners with a clear and discernible picture of the moisture present in their roofing system. Equipped with this evidence, Parsons Roofing can recommend accurate, fact-based solutions that meet the unique needs of each property.

Benefits Of A Drone Roof Survey

- Drone equipped with infrared camera accurately detects leaks

Detailed Roof Analysis Report

- A drone scan allows our team to provide you with a detailed health report for your roof

- Concise and comprehensive report regarding your roof’s condition

Time And Cost Savings

- Areas of roof saturation are pinpointed

- Solutions for potential issues and valuable for budget forecasting

- 5 to 10 year budget-forecasting

Infared Thermography Benefits

Targeted Roof Repairs

- Locating exact leak points on low-slope roofs can be challenging. The location of the roof defect and the area of the water intrusion in the building are not always directly in line with one another.

- Many times, the roof issue is twenty or thirty feet away from internal damage. Infrared scans help narrow the search for possible leak points by providing an actual image of the moisture content in the roof.

Damage Prevention

- Moisture left unchecked in a roofing system can compromise the structural integrity of a building. Rotten wood and rusted steel decks present a safety issue for technicians.

- Accessing the roof can dramatically increase the cost of a roof replacement. Interior damage can impact sensitive electrical and mechanical systems and provide a breeding ground for mold.

Periodic Monitoring

- Implementing thermal roof scans into a preventative maintenance program is a proactive way to monitor the health of your roof.

- Repairing issues at their infancy will limit the scope and cost of the repairs while protecting the building structure, its contents, and business operations.

When To Request A Roof Moisture Survey?

Recovering A Roof

- Avoiding the cost of a full tear-off and recovering the existing roof is an acceptable and cost-effective solution if the current system is free of moisture. Many times, contractors will rush through the due diligence phase to submit a quick and cheap bid proposal. Installing a new roofing system over an unknown substrate is not conducive to long-term performance.

Roof Restoration

- With warranty periods of up to 20 years, Silicone Roof Coatings has become one of the fastest-growing segments in commercial roofing applications. Similar to a roof re-cover, it is imperative there is no moisture in the existing roofing system before application. Improper applications of over-saturated substrates can cause the coating to fail and peel. When properly installed, Silicone Coatings provide a service life that far exceeds the available warranty periods.

Property Acquisition

- Unfunded capital expenditures and deferred maintenance can kill a real estate deal. An infrared moisture survey offers buyers an accurate snapshot of the existing roof conditions. Understanding where the roofing system is in its life cycle allows the buyer to forecast a budget as well as develop a maintenance plan to protect the investment.

Contact Us Today

How Are Commercial Moisture Surveys Performed?

Precise Site Conditions

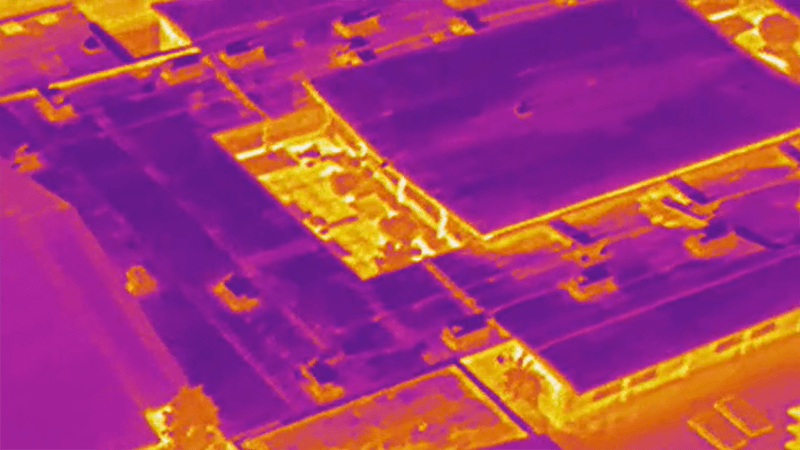

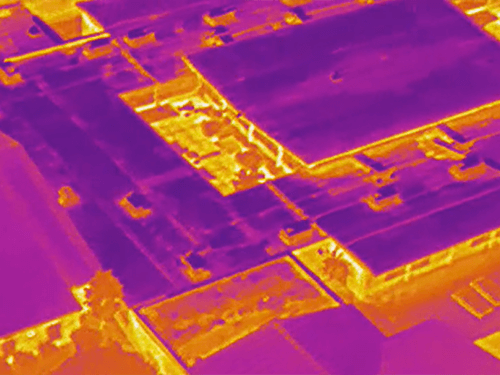

- Infrared surveys are only valid on low-slope roofs. The surface needs to be dry and relatively clean.

- The ideal setting is mostly sunny and warm during the day with a temperature differential of 10 or more degrees after the sunsets.

- During the day the solar load heats both the roof surface and the moisture hidden beneath the surface.

- As the sun sets, the roof surface cools quickly while the moisture in the substrate retains the heat.

- The infrared imagers detect this temperature differential and provide a clearly defined image of probable saturated areas.

Specialized Equipment

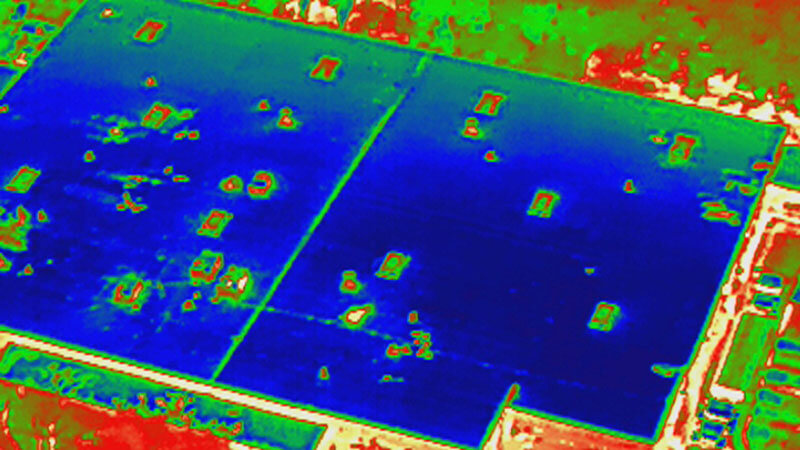

- Drones fitted with thermal cameras can capture the entire scope of a large building through the use of aerial imaging.

- Our DJI Inspire Drone with Zenmuse XT FLIR thermal imaging camera1 is capable of producing high-quality video and images in multiple color scales.

- Our Flir E8 Handheld Thermal Imaging Camera is excellent for inspecting smaller areas from the rooftop surface.

Interpreting The Results

- Our consultant will then review all of the evidence.

- They will interpret the results and identify the areas on the thermal photos.

- As well as standard photos so the customer can evaluate the information in a concise format.

Verification

- Infrared photos and videos are an excellent tool to indicate likely issues.

- However, it is essential for a technician to verify the findings.

- Field verification can be accomplished by coring the roof or through non-invasive impedance scanners.

- Parsons utilizes a Tramex RWS Roof and Wall Scanner to confirm results.

- This device functions by transmitting a low-frequency electronic signal into the material and measuring the strength of the current.

- We can test materials down to a depth of 4” utilizing this nondestructive method.

Related Posts

Posts from our resources related to Infrared Thermography