Ethylene Propylene Diene Terpolymer is more commonly known as an EPDM roof. This rubber roofing membrane is an extremely tough, durable, and long-lasting material, but it can have its drawbacks. As one of the most common and least expensive roofing materials available, EPDM is in wide use as a commercial roofing solution. But while it may save money upfront, repairs and replacement costs can outweigh the initial economies. Keep reading to learn more about repairing or upgrading your EPDM roof.

What is EPDM?

Similar to the inner tubing that’s used in bike tires, EPDM is made from recycled rubber products with some other materials included during the manufacturing process to add durability and strength (i.e., sawdust, slate). While EPDM is generally black in color, lighter shades are gaining in popularity due to their ability to reflect the sun, although this may cut down on UV protection and the roof’s durability.

The most common EPDM application method is to fully adhere or glue down the entire membrane on top of the roofing system and then reinforce the seams and flashing with rubber tape. EPDM roof systems generally have a life expectancy of between 20 and 35 years, depending on environmental issues such as extreme weather. The EPDM material is also waterproof when professionally installed and is virtually fire-resistant.

What are the Drawbacks of an EPDM Roof?

While they are inexpensive and easy to install, EPDM roofs have several drawbacks worth noting:

- Seam Failure — The seams of the roof may fail if the adhesives wear out from time and exposure.

- Flashing Failure — Flashing reinforcement may fail, which allows water to penetrate the roof.

- Protrusions — Protrusions through the roof, i.e., HVAC units, vents, or pipes, can create natural failure points where the roofing pulls away, leaving an exposure vulnerable to moisture, infestation, and extreme weather.

- Shrinkage — Over time, EPDM rubber is susceptible to shrinkage, which results in the membrane pulling away from the walls and flashing, and opening seams.

- Difficult to Locate Punctures — EPDM roofing is vulnerable to punctures and tears of the membrane, which can be difficult to locate due to its color or if there is river rock ballast covering the surface. Often additional punctures can occur when repair workers are walking on the roof, creating even more problems.

- Water Damage — Once a seam opens, water can easily reach the insulation and decking, causing even more extensive damage and destroying the integrity of the roof.

Is Repairing or Upgrading an EPDM Roof an Option?

Yes, repairing or upgrading an existing EPDM roof can be highly effective. As with many types of construction repairs, the process involves taking similar and compatible materials and rebuilding the roof in a specific location with those similar supplies. A reputable roofing contractor will always repair an EPDM roof with the materials specified by the original manufacturer.

- Benefits of Repairing an Existing EPDM Roof

- Cost-Effectiveness — By repairing the damage or problems, you obviously extend the life of the existing roof. In many cases, this could be by many years or even decades.

- Very Low Invasiveness — Unlike some other types of roofing repairs, repairing an EPDM roof is relatively non-invasive. Businesses can proceed as normal in all but the most extreme cases.

- Quick Turn Around — As a general rule, EPDM roof repairs are completed quickly with little disruption or mess.

- Drawbacks of Repairing an Existing EPDM Roof

- Failure Rate — Repairs on an EPDM roof often don’t last long with further problems down the road.

- Finding the Location is Often Problematic — It can be difficult to locate the exact area that needs to be repaired, especially if there is an existing rock ballast in place. One possible solution is to engage a professional roofing contractor that has specialized infrared thermography capable of detecting moisture and potential leaks.

- Ineffective Against Extensive Damage or Deterioration — The more damage that is repaired, the more the likelihood of additional integrity failures.

What Makes a Good vs. Bad Candidate for Repairing?

In general, if the location of the leaks is within a small area of the roof and can be repaired with like material and the roof is not too old or showing signs of wear with most of the seams holding well, it is a strong contender for a successful repair. Also, if there are no large amounts of saturation identified under the roof, which typically happens when a repair is postponed or delayed allowing further damage to occur.

On the other hand, if there are multiple leaks on the roof in various locations or if the seams are no longer holding due to failing adhesives, the roof may not be a good contender. Also, if the membrane is old and brittle, the material is falling between the scrim, or if the roof is saturated beneath the surface, it may be time to consider a replacement.

Basically, if the EPDM roof is not at the end of its usable life and only has a few areas with leaks, it’s prime for repairs.

4 Options for Repairing or Upgrading an EPDM Roof

First on our list is Silicone Coating, which we will explain in detail. Then please be sure to learn more about the other four types of repairs available for EPDM roofs in our follow-up post.

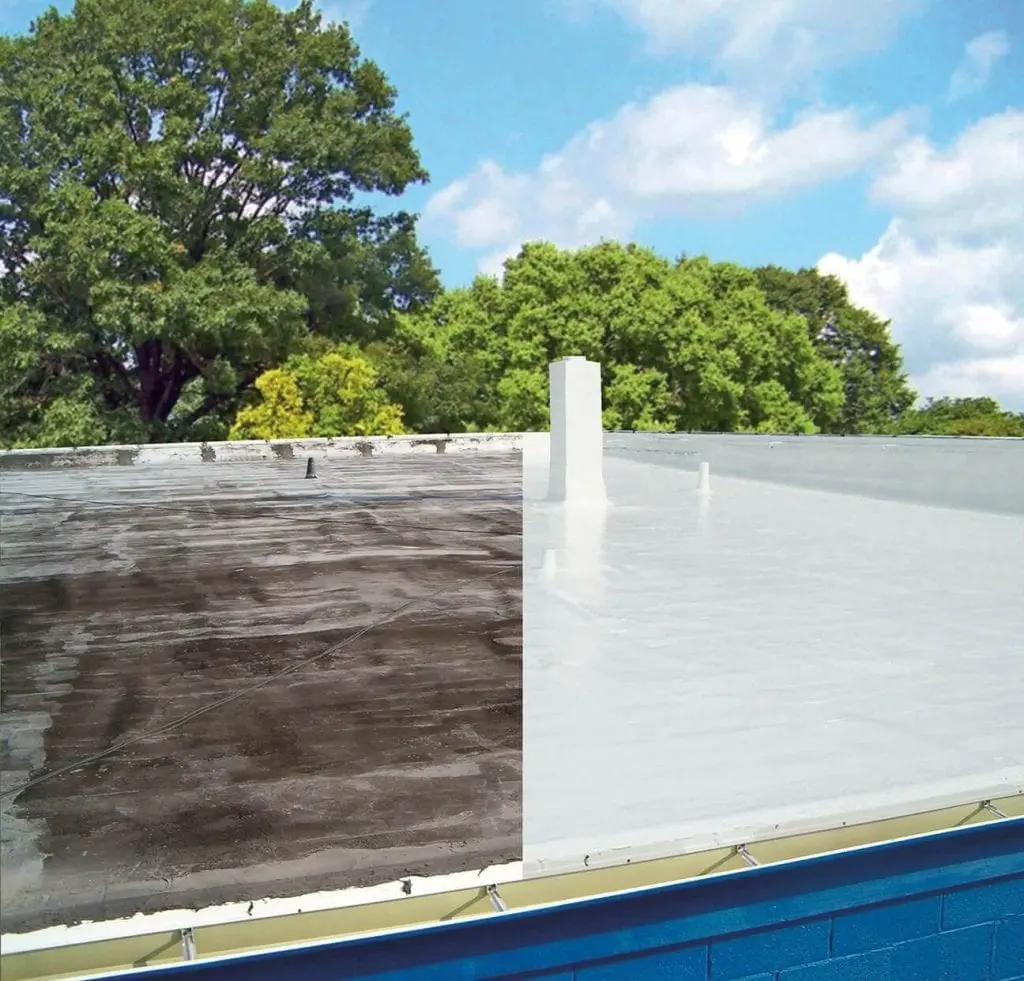

Silicone Coating

A silicone coating is just what’s implied: a viscous silicone fluid is applied directly over the existing roof membrane. In this application, the silicone penetrates any punctures or openings, creating a water-tight barrier. When applied correctly, it achieves a smooth, even coat that cures and becomes impenetrable.

Silicone may be a good solution for repairing or upgrading your roof when the following conditions exist:

- The roof membrane is fully adhered to with no seam issues or membrane shrinkage visible.

- The roof is at the end of its usable life but is in good repair with minimal deviations.

- Following an infrared thermography scan, it’s determined that the roof has little to no saturation points, and there has not been damage to the underlying insulation or structure.

- The membrane seams are fully intact and not failing due to adhesive failure.

- The roof is not covered in a ballast of any type.

Conversely, if any of the items above are missing, the roof may be a poor candidate for repairing or upgrading and better served with a full replacement. This would include a shrinking membrane or seals that are broken or generally poor condition of a roof that is near the end of its usable life. Serious moisture penetration issues from untreated punctures or fissures in the membrane, or ballast that impairs the application process can also warrant a full replacement.

Benefits

Using silicone coating as a repair material has benefits that make it an excellent choice for many customers, including:

- Silicone coating is a very cost-effective method that is long-lasting, durable, and flexible, allowing for normal roof contracting and expanding.

- Properly applied, silicone coating may last up to 15 years.

- Because of its impressive performance, it qualifies for most manufacturers’ NDL warranties from leading manufacturers.

- Silicone coating is typically white and has excellent reflectivity that leads to energy savings long term.

- The repair process is non-invasive.

Drawbacks

Drawbacks for this type of repair may include:

- This type of silicone coating relies on the structural integrity of the existing substrate for stability, and a full inspection is crucial to ensuring success.

- Financially, the long-term 20-year warranties available with silicone coating repairs are not as cost-effective as a more substantial re-cover of the entire roof.

- This type of repair relies on the applicators’ skill to properly apply an even roof surface rather than the roof being fabricated perfectly in a factory like the original EPDM membrane.

Silicone Coating Repairs are Recommended for:

- Existing EPDM roof surfaces that are smooth, unblemished, and not moisture saturated.

- Customers who are looking for a manufacturer’s NDL warranty at a reduced cost.

- Customers are interested in energy efficiency and desire more reflectivity to reduce heat inside the building, as well as reduced energy costs.

In this article, we have discussed EPDM roofs in terms of their composition and the pros and cons of this type of roofing system. We also began a discussion on the best methods for repairing or upgrading, starting with a silicone coating. In the next installment, we will discuss three more types of repair options, including single-ply recovers, wind-vented systems, and full replacements.

Parsons Roofing has been installing, repairing or upgrading, and maintaining commercial roofs in the greater Atlanta area for years. If you want to work with a roofing contractor that you can trust and be assured that they will be here in the future, work with us. Contact us to discuss EPDM roofing repair today.

We will continue our discussion on repairing or upgrading EPDM roofs in the companion article – 4 Options When Repairing or Upgrading Your EPDM Roof – Part II.