Covington Restoration

Ensuring the utmost safety and preparation for the roofing project, we provided and set up safety lines around the perimeter of the roof in strict accordance with OSHA fall protection standards. Concurrently, a designated work area was coned off to control access and enhance safety measures. To further comply with OSHA fall protection standards, anchor points for harnesses were strategically provided.

Before the main construction phase began, a meticulous cleanup process was initiated, involving the removal of all loose debris from the roof surface, followed by appropriate disposal.

Prior to coating application, adhesion tests were performed on all roof surfaces to verify substrate adhesion. The roof then underwent a thorough pressure wash to ensure a clean surface conducive to coating.

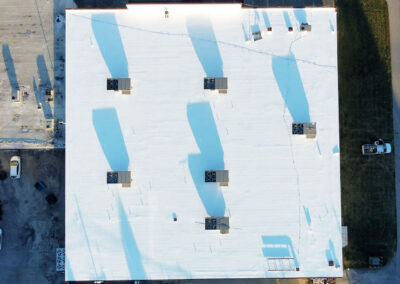

As part of the restoration process, skylights were removed and replaced with new ones. GE Enduris flashing grade coating was then applied to various locations, including pipes, vents, curbs, drip edges, large cracks, and pitch pockets. The roof received a final application of GE Enduris silicone coating, aligning with GE’s specifications for a 15-year No Dollar Limit Warranty. Upon completion, any areas requiring additional material was then touched up to meet the manufacturer’s minimum requirements, culminating in a thorough and high-quality roofing solution.

Save money with an enduring roof coating

An excellent low-cost option is restoring a roof with an elastomeric coating. Restorations are fully tax-deductible in a year. Restoration is the most economical way to fully repair a roof and receive a manufacturer’s NDL warranty as well.

Call for a Roof Inspection:

(678) 756-0224

Commercial Silicone Coating Projects

A few completed Silicone Coating Portfolio projects by Parsons Roofing Company.

Related Posts

Posts from our resources related to Silicone Coatings and Roof Restorations

Commercial Roofing Restoration

Contact our commercial roofing team today to request an inspection for your Restoration roofing project.